Documentation > Instruction Manuals

|

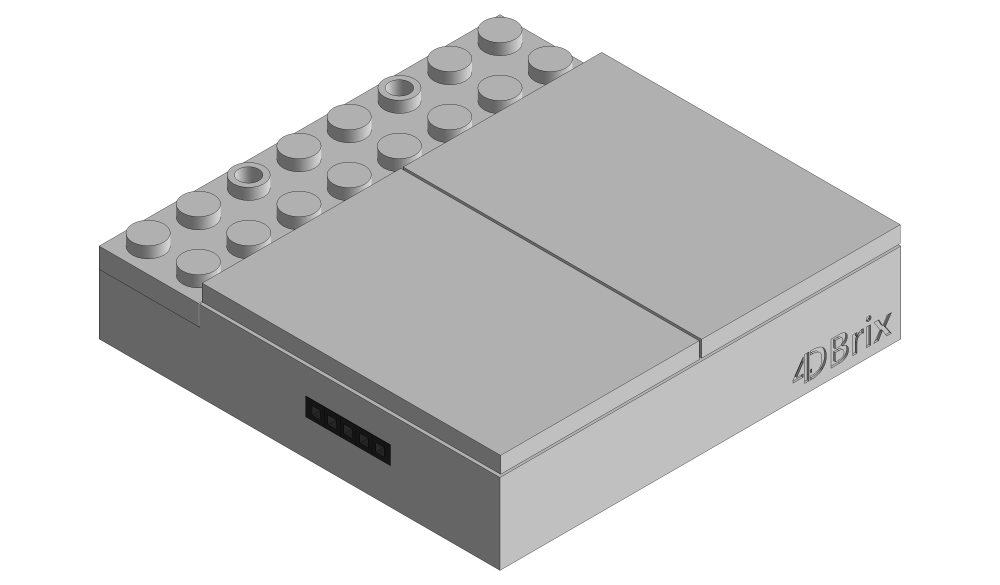

Servo Control Button - 2.01.101

Introduction

Features

Supported Motors and Tracks

The servo control button can handle the following servo based actuators:

The control button can be used with the following tracks:

Modes of Operation

In order to send the correct instructions to the motors, the control buttons have to be configured for that specific device.

The control buttons can be configured without the need of an external computer or programmer.

The control buttons have two modes:

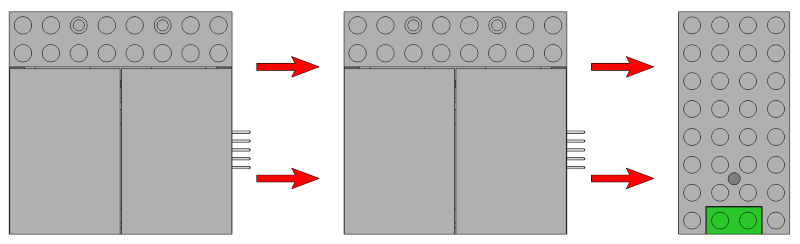

Identifying the Control Button Type

There are several types of control buttons. You can identify a servo control button by looking at the back panel.

The servo control buttons have:

Installation

This section explains how to assemble your control button system.

Please read the section on how to configure your control buttons before assembling them into a control panel.

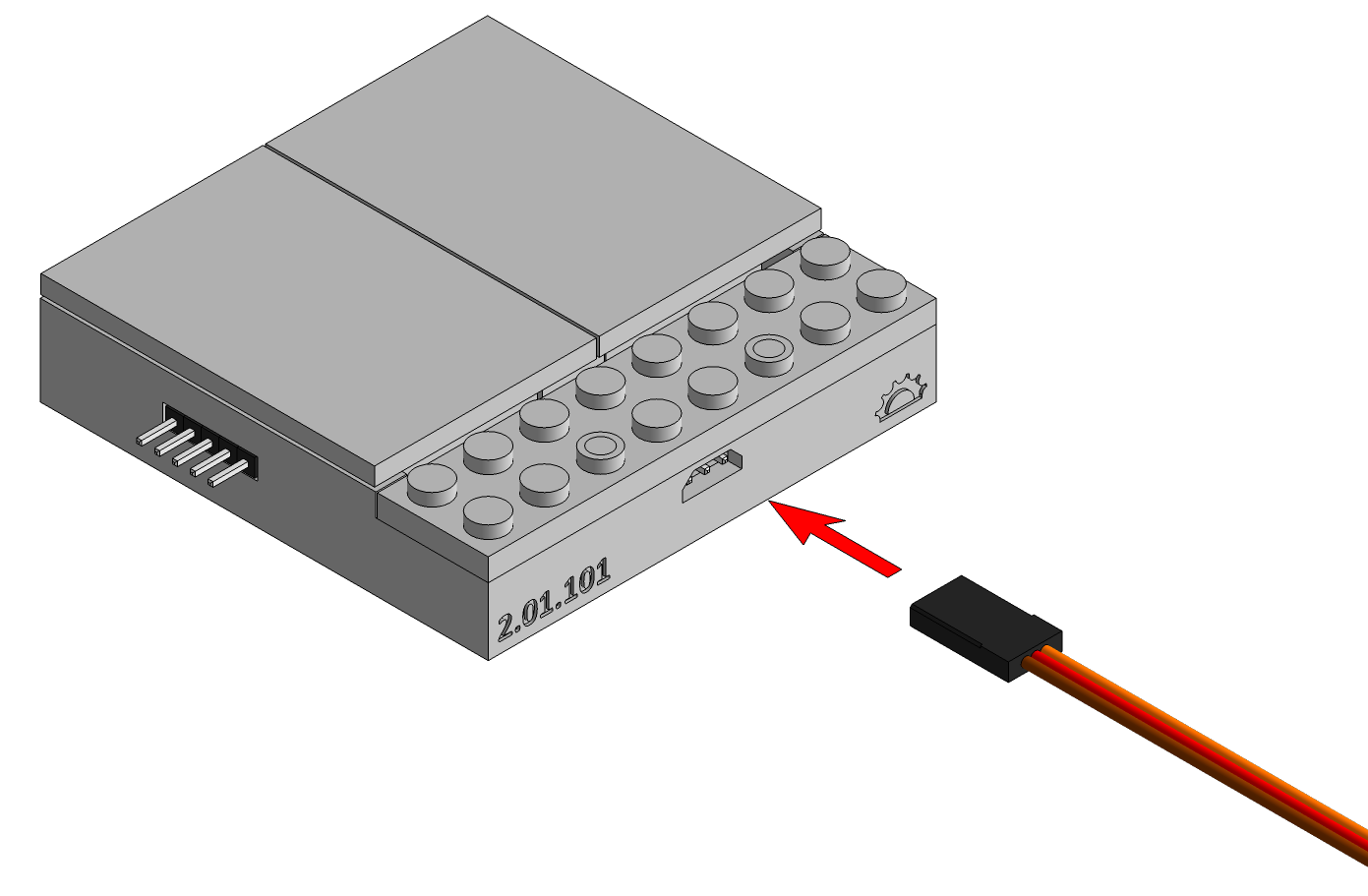

Connecting the Control Button

The control buttons are powered by a power brick.

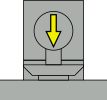

Make sure the power brick is switched off and slide the 5 pin connector of the control button into the 5 pin receptacle of the power brick.

You can also power a control button by inserting its 5 pin connector into the 5 pin receptacle of another control button that is already powered.

As such you can create a panel of control buttons all powered by the same power brick.

You can combine servo control buttons and light control buttons, in any order you want, into one control panel.

Connecting the Motor

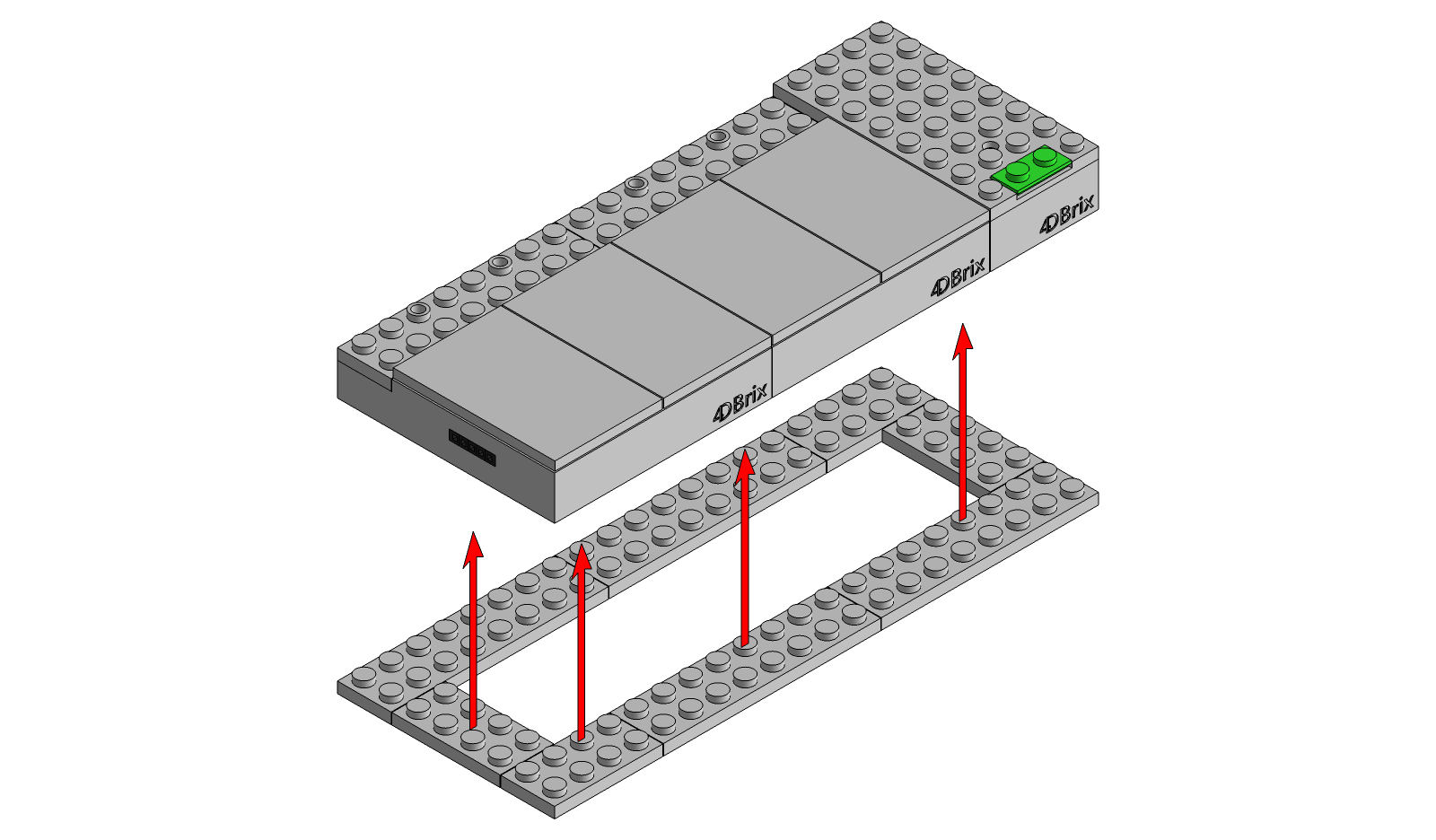

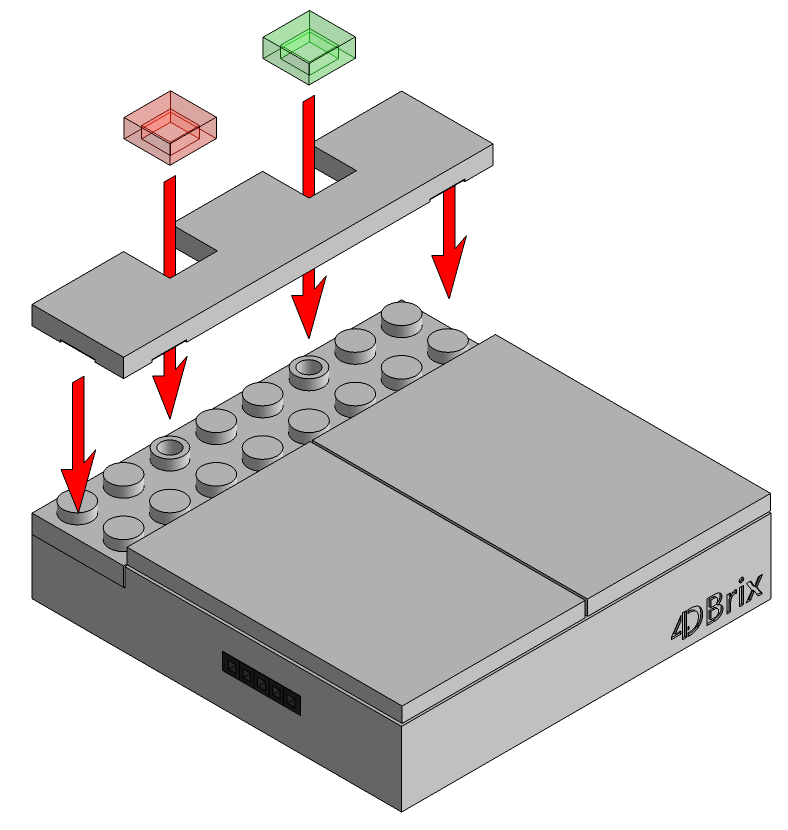

Building a Control Panel

The control buttons connect to each other with 5 pin connectors.

The base of the control buttons are fully anti-studded.

So once they are connected you can secure the connection between the control buttons by adding LEGO® plates. The control buttons have a foot print of 8 x 8 studs.

The top of the control button is studded. You can customize it by added transparent 1x1 bricks or tiles (not provided) to change the color of the LEDs. You can cover the other studs with the custom tile that is provided with your control button. Alternatively you can use standard LEGO® tiles (not provided).

Powering Up Your System

To power up the system, push the green button of the power brick.

The LED of the power brick will immediately light up. The LED should be green.

If the LED is red, shut down the system and consult the power brick manual on how to resolve the issue.

The control buttons connected to the power brick will start up, one by one, in a random order.

This is an intended behavior.

Each control button executes a random delay between 0 and 1 second while starting up.

That's to avoid that all control buttons power up at the same time and cause a peak in power consumption.

At start up, all control buttons will go to their default state: the state defined by the left button / LED.

Except when the button is configured for a monoswitch, than it will start up in the stop position (both LEDs on).

Configuration

The control buttons have been programmed to handle a range of different motors on a variety of switches.

Before you can use your control button, it has to be configured for the motor/switch combination you want to use it for.

The selected settings are stored in the control button and will be reloaded the next time you switch the control button on.

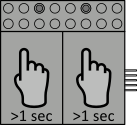

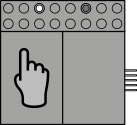

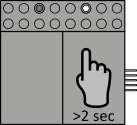

Navigating Configuration Mode

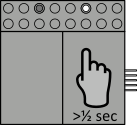

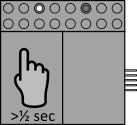

To enter configuration mode, hold both buttons down for more than 1 second.

When the control button enters configuration mode, both LEDs will rapidly flash 3 times. So hold both buttons down and release them when both LEDs start flashing.

Each time the button changes mode or moves on to a next step of the configuration, both LEDs will flash 3 times.

The table below gives an overview of the operations you can perform in configuration mode.

Device Selection

The first step of the configuration is to select the type of motor you want to control.

Anti Buzz Setting

The antibuzzing setting helps to reduce buzzing of the servos in the track switch motors, decoupler, monorail switch motors.

Trimming Angles

The boom barriers might not be perfectly vertical / horizontal when the barriers are open / closed. This can be corrected with a set of two trimming angles.

A standard track switch configuration is an R motor on a right turn LEGO® switch while an inverse track switch configuration is an L motor on a right turn LEGO® switch.

The list below provides a detailed overview of the of all the standard and inverse motor/switch combinations.

Standard:

Controlling Your Layout

Operating the Buttons

These control buttons are not mechanical switches like the 12V LEGO® controls from the eighties.

They contain a microcontroller and can thus be used in a multi-functional way.

There are two ways to control the behavior of the button:

The operation the button performs also depends on the configuration. This section provides an overview on how to operate the control button.

The operation the button performs also depends on the configuration. This section provides an overview on how to operate the control button.

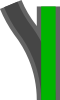

Mode 1: Track Switch Motor - Standard

If the control button is configured for a standard motor/switch combination, the switch will respond as shown in the table below.

If you want the switch to respond in the opposite way, configure your control button for an inverse motor/switch combination.

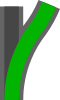

Mode 2: Track Switch Motor - Inverse

If the control button is configured for an inverse motor/switch combination, the switch will respond as shown in the table below.

If you want the switch to respond in the opposite way, configure your control button for a standard motor/switch combination.

Mode 3: Decoupler

If the control button is configured for a decoupler, the decoupler will respond as follows:

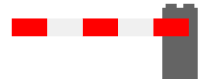

Mode 4: Boom Barrier

If the control button is configured for a boom barrier motor, the motor will respond as follows:

Mode 5: Monoswitch

If the control button is configured for a monoswitch, the train will respond as follows:

Mode 6: Monorail Switch - Right

If the control button is configured for a right turn monorail switch, the switch will respond as shown below.

If you want the switch to respond in the opposite way, configure it as a left turn monorail switch.

Mode 7: Monorail Switch - Left

If the control button is configured for a left turn monorail switch, the switch will respond as show below.

If you want the switch to respond in the opposite way, configure it as a right turn monorail switch.

Mode 8: Monorail Cross Switch

If the control button is configured for a cross switch, the switch will respond as follows:

Mode 9: Double Crossover Motor

If the control button is configured for a double crossover motor the switch will respond as shown in the table below.

Note that this configuration is meant for crossover motors on a LEGO® double crossovers (Set 7996-1).

4DBrix™ double crossovers use a separate motor for each switch and need to be controlled with mode 1 or 2.

Mode 10: Push Button

This mode has been added for future applications.

It does not actuate the motor, it just generate a signal indicating the button has been pressed.

If the buttons are connected to a computer running nControl the computer can detect the button press and respond accordingly.

Mode 11: Toggle Button

This mode has been added for future applications.

It does not actuate the motor, it just generate a signal indicating the button has been pressed.

If the buttons are connected to a computer running nControl the computer can detect the button press and respond accordingly.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||